Summary

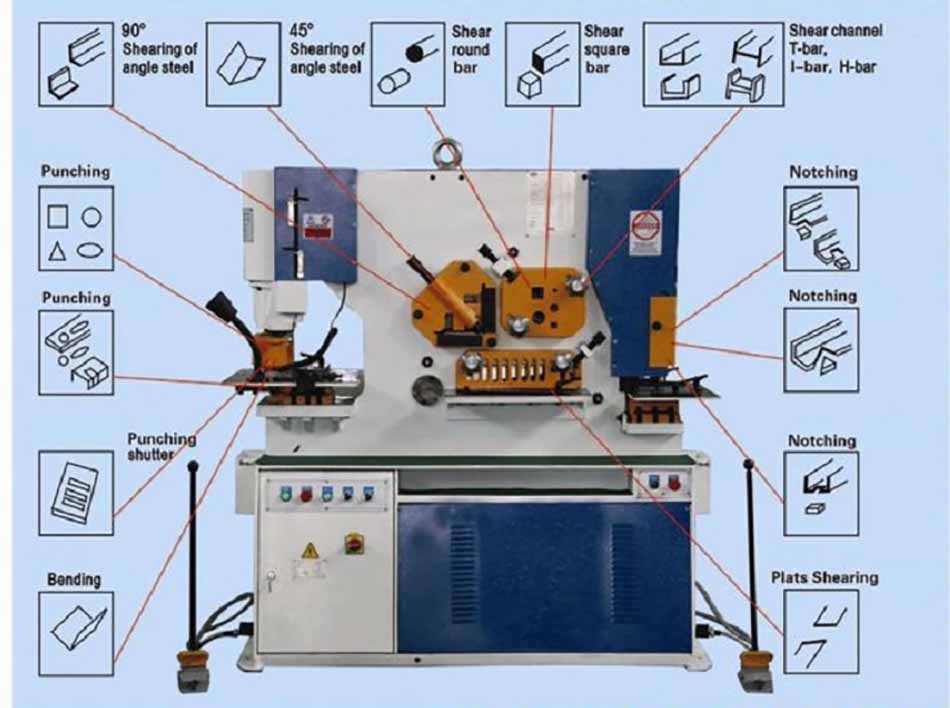

The multi functional iron worker(Q35series) can cut and punch all kinds of materials such as plate,square bar,angle,round bar,channel and so on. It has another special function,that is ,it can also bend the plate below 500mm. With its multifunction,the machine is your first choice among the counterpart machine. All the components are of the highest quality in their safety ,function,capability and maintenance.

|

Technical Data

|

|

Model

|

Q35Y-16(IW-60)

|

Q35Y-20(IW-90)

|

Q35Y-25(IW-120)

|

Q35Y-30(IW-140)

|

|

Working pressure(KN)

|

600

|

900

|

1200

|

1400

|

|

Max. cutting thickness(mm)

|

16

|

20

|

25

|

26

|

|

Max. cutting length(mm)

|

400

|

480

|

600

|

600

|

|

Tensile strength of sheet metal

(N/mm2)

|

≤450

|

≤450

|

≤450

|

≤450

|

|

Shear angle(deg)

|

7

|

8

|

8

|

8

|

|

Stroke of ram(mm)

|

80

|

80

|

80

|

80

|

|

(stroke times)(min)

|

8

|

8

|

8

|

8

|

|

Depth of throat(mm)

|

300

|

355

|

400

|

600

|

|

Max.Capacities(mm)

|

25×16

|

30×20

|

35×25

|

38×28

|

|

Main motor(KW)

|

4

|

5.5

|

7.5

|

11

|

|

Length of machine tool(mm)

|

1650

|

1950

|

2355

|

2680

|

|

Width of machine tool(mm)

|

800

|

900

|

980

|

1060

|

|

Height of machine tool(mm)

|

1780

|

1930

|

2100

|

2350

|

|

Weight of machine tool(kg)

|

1900

|

2600

|

4800

|

6800

|

|

PUNCHING METRIC(mm)

|

|

Max. Capacities

|

25×16

|

30×20

|

35×25

|

38×26

|

|

Max. Stroke Length

|

80

|

80

|

80

|

80

|

|

Throat Depth Standard

|

305

|

355

|

400

|

600

|

|

Working Height

|

1030

|

1084

|

1142

|

1209

|

|

SHEARING

|

|

Flat Bar

|

250×16

|

330×20

|

300×25

|

355×30

|

|

Alternative

|

400×8

|

480×10

|

600×16

|

600×20

|

|

Blade Length

|

410

|

485

|

620

|

610

|

|

Working Height

|

890

|

894

|

891

|

897

|

|

ANGEL CUTTING

|

|

At 90°cut

|

125x125×12

|

140x140×12

|

160×160x16

|

180x180×16

|

|

At 45°Mitre

|

70×10

|

70×10

|

70×10

|

70×10

|

|

Working Height

|

1130

|

1139

|

1200

|

1220

|

|

SECTION CUTTING

|

|

Round/Square Bar

|

45

|

50

|

60

|

65

|

|

Channel/I bar

|

130×65

|

160×88

|

200x100

|

280×122

|

|

T bar

|

90×12

|

90×12

|

90×12

|

90×12

|

|

NOTCHING

|

|

Material Thickness

|

10

|

13

|

14

|

16

|

|

Width

|

57

|

57

|

57

|

57

|

|

Depth:Vee -Rect.

|

60-90

|

60-90

|

60-90

|

60-90

|

|

Working Height

|

890

|

883

|

886

|

898

|

Siemens Electrical component:

Our standard die and blade on the machine (free):

1 set of hole punching die,

1 set of angle steel blade,

1 set of square and round bar blade

1 set of shearing plate blade

1 set of notching blade.

1 set of bending tool

If you need the other special dies and tool profiles , you just tell us then we can make just according to your request.

Optional Punching tools :

Profile :

Our workshop:

After Sales Service

1.Our guarantee time is 5 years from B/L date. If any component is damaged during guarantee time,we can send the component to the customer by DHL,TNT freely.

2.Our factory can send our engineer to the customer’s factory install,commission and training freely. The customer provide the double trip tickets,food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

3.Our factory provide the service for the customer forever,if the customer need operation help,can contact us by MSN,Skype,Email and Telephone at any time,we provide 24 hours on-line service.