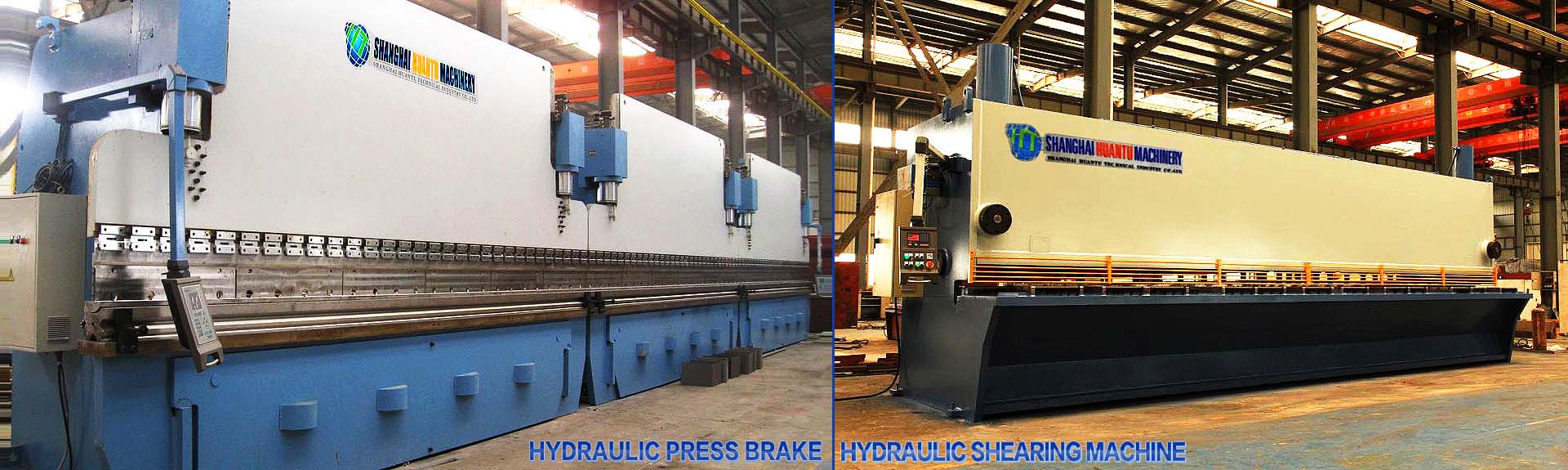

Streamlined design,high speed,high precision,high rigidity,CNC sheet metal press brake.

Electro hydraulic servo system,full loop controlling the synchronization of the upper beam.

Hydraulic compensation on crowning of worktable and deformation compensation of throat,ensuring good bending strength and precision.

Back gauge driven by digital AC servo motor,moved with long-stroke ball screw,linear guideway guiding.

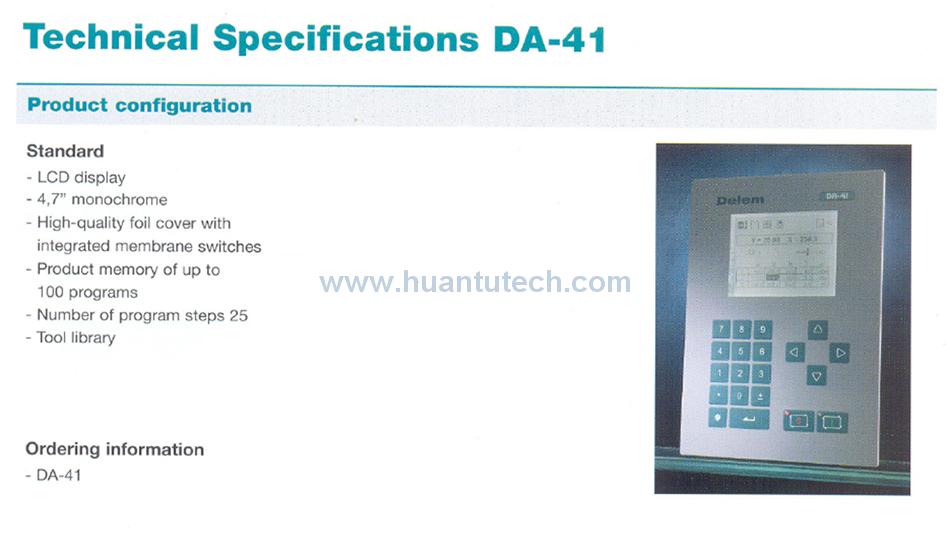

Control Technology

The synchronization of press brake adopt the technology of full loop electro hydraulic servo control,the positioning signal of the upper beam are feed back by raster (light-ruler) to CNC system and CNC system will check the opening size of synchronization valves,adjusting the inlet oil amount,to realize the synchronizing movements of the upper beam (Y1,Y2),and keep the worktable are always parallel situation. Following the situation of sheet metal to be bended,CNC system control automatically the amount of the crowning compensation of worktable to realize that angle being bended of workpiece can keep same along the full workpiece length.

Crowning Compensation

Crowning compensation system on worktable can make a workpiece having a same precision full along the length of the work piece. A crowning compensation system is composed of a group cylinders in line in worktable,which can from a relative movements of worktable,forming a curve needed of adding conves to worktable,to ensure unchanged the relative position to the upper beam of worktable after the worktable being under pressure. The crowning compensation amount is automatically calculated out by CNC system according to the worktable’s situation.

Key components of press brake

Valves: Rexroth,Germany

Main Electrical components: Siemens,Germany

Main Motor: Siemens,Germany

Pressure gauge: Hawe,Germany

Oil seals: VALQUA,Japan.

Oil filter: Compass,Taiwan,China.

Precision of machine

Ram of the machine (precision of X,Y1,Y2,V axes)

Position precision of the machine ±0.01MM

Reposition precision of the machine ±0.01MM

Working environment of machine

Power supply: 380 V/3 phases/50 Hz(Or 220V,60hz or We can make as your request)

Temperature: 5℃~+50℃

Workshop environment: cleaning without dust

Hydraulic system

Y1,Y2 axes use the electrical-hydraulic proportional servo valve technique. Hydraulic system is made in Rexroth,Germany.

The oil pump: internal gear pump,Chengjie,Shanghai.

The dynamic seal rings for main oil cylinder is made in VALQUA,Japan,which have the perfect sealing effect and long life.

The oil level can be displayed clearly by the oil level meter set on oil tank,which has the oil filter mechanism and blocking alarm function.

Extra loading overflow protecting function on hydraulic system.

We have following Press Brake Models :

|

Parameter Specification

|

Nominal Pressure

|

Length of Working Table

|

Distance between uprights

|

Throat depth

|

Ram Stroke

|

Main Motor Power

|

|

(kn)

|

(mm)

|

(mm)

|

(mm)

|

(mm)

|

(kw)

|

|

WC67Y-40/2500

|

400

|

2500

|

2050

|

200

|

120

|

5.5

|

|

WC67Y-63/2500

|

630

|

2500

|

2050

|

250

|

120

|

5.5

|

|

WC67Y-63/3200

|

630

|

3200

|

2520

|

250

|

120

|

5.5

|

|

WC67Y-80/3200

|

800

|

3200

|

3020

|

320

|

120

|

7.5

|

|

WC67Y-80/4000

|

800

|

4000

|

3020

|

320

|

120

|

7.5

|

|

WC67Y-100/2500

|

1000

|

2500

|

2020

|

320

|

120

|

7.5

|

|

WC67Y-100/3200

|

1000

|

3200

|

2520

|

320

|

120

|

7.5

|

|

WC67Y-100/4000

|

1000

|

4000

|

3020

|

320

|

120

|

7.5

|

|

WC67Y-100/5000

|

1000

|

5000

|

4010

|

320

|

120

|

7.5

|

|

WC67Y-125/2500

|

1250

|

2500

|

2020

|

320

|

120

|

7.5

|

|

WC67Y-125/3200

|

1250

|

3200

|

2520

|

320

|

120

|

7.5

|

|

WC67Y-125/4000

|

1250

|

4000

|

3020

|

400

|

120

|

7.5

|

|

WC67Y-125/5000

|

1250

|

5000

|

4010

|

320

|

120

|

7.5

|

|

WC67Y-160/3200

|

1600

|

3200

|

2520

|

320

|

200

|

11

|

|

WC67Y-160/4000

|

1600

|

4000

|

3020

|

320

|

200

|

11

|

|

WC67Y-160/5000

|

1600

|

5000

|

4010

|

320

|

200

|

15

|

|

WC67Y-160/6000

|

1600

|

6000

|

4850

|

400

|

200

|

15

|

|

WC67Y-200/3200

|

2000

|

3200

|

2520

|

400

|

200

|

15

|

|

WC67Y-200/4000

|

2000

|

4000

|

3020

|

400

|

200

|

15

|

|

WC67Y-200/5000

|

2000

|

5000

|

4010

|

320

|

200

|

15

|

|

WC67Y-200/6000

|

2000

|

6000

|

4850

|

400

|

200

|

15

|

|

WC67Y-250/3200

|

2500

|

3200

|

2520

|

400

|

250

|

18.5

|

|

WC67Y-250/4000

|

2500

|

4000

|

3020

|

400

|

250

|

18.5

|

|

WC67Y-250/5000

|

2500

|

5000

|

4010

|

400

|

250

|

18.5

|

|

WC67Y-300/4000

|

3000

|

4000

|

3020

|

400

|

250

|

22

|

|

WC67Y-300/5000

|

3000

|

5000

|

4010

|

400

|

250

|

22

|

|

WC67Y-300/6000

|

3000

|

6000

|

4850

|

400

|

250

|

22

|

|

WC67Y-400/5000

|

4000

|

5000

|

4010

|

400

|

250

|

30

|

|

WC67Y-400/6000

|

4000

|

6000

|

4850

|

400

|

250

|

30

|

|

WC67Y-500/6000

|

5000

|

6000

|

4850

|

400

|

300

|

37

|

|

WC67Y-600/7000

|

6000

|

7000

|

5600

|

400

|

300

|

45

|

|

WC67Y-700/7000

|

7000

|

7000

|

5600

|

400

|

300

|

45

|

|

WC67Y-1000/8000

|

10000

|

8000

|

6000

|

500

|

450

|

2*37

|

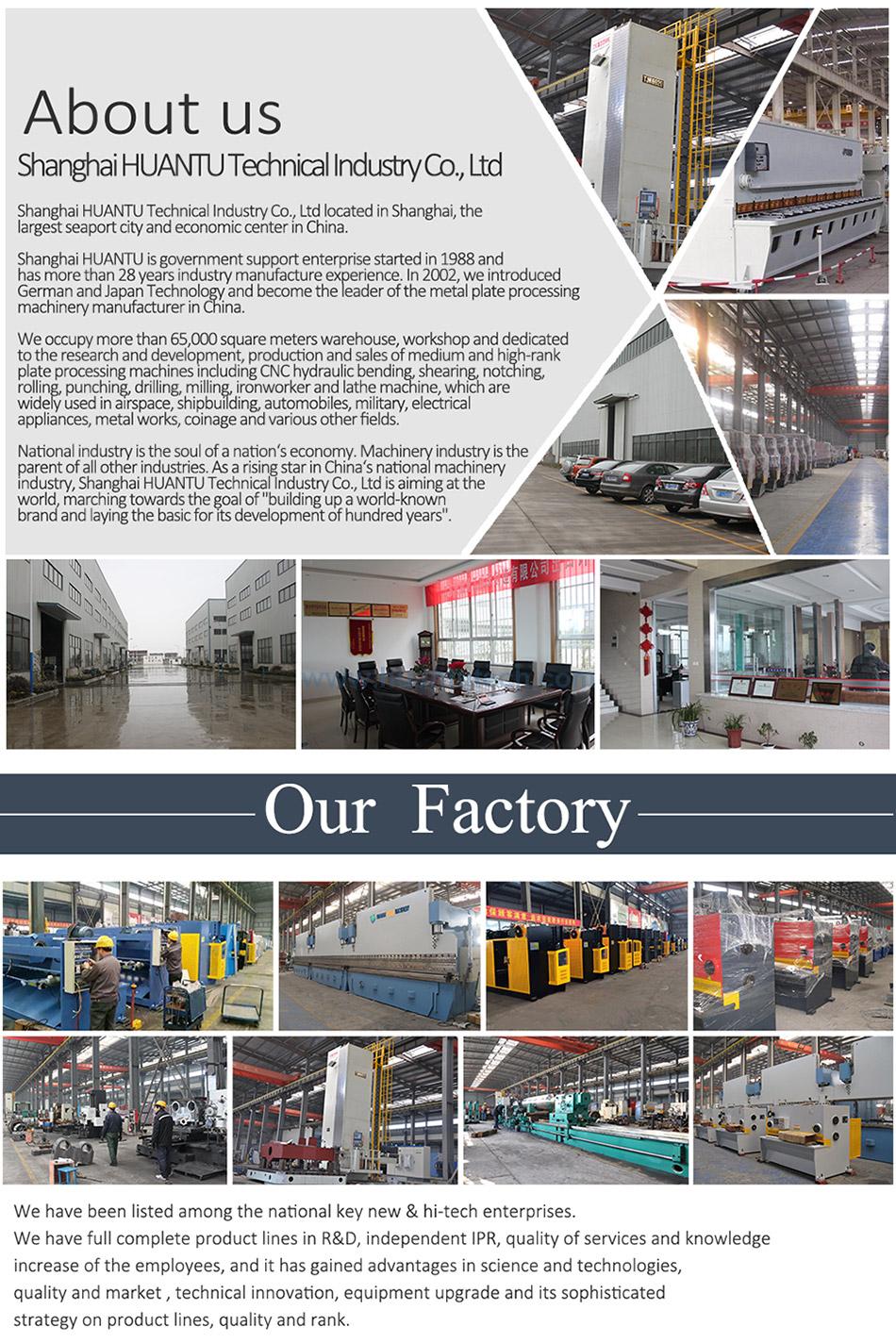

Our Machine Pictures:

Our Market:

(Our machines have been sold to more than 90 oversea countries,all our customers are very satisfy about our quality)